Installation Elements Of Linear Displacement Sensor

Installation elements of linear displacement sensor

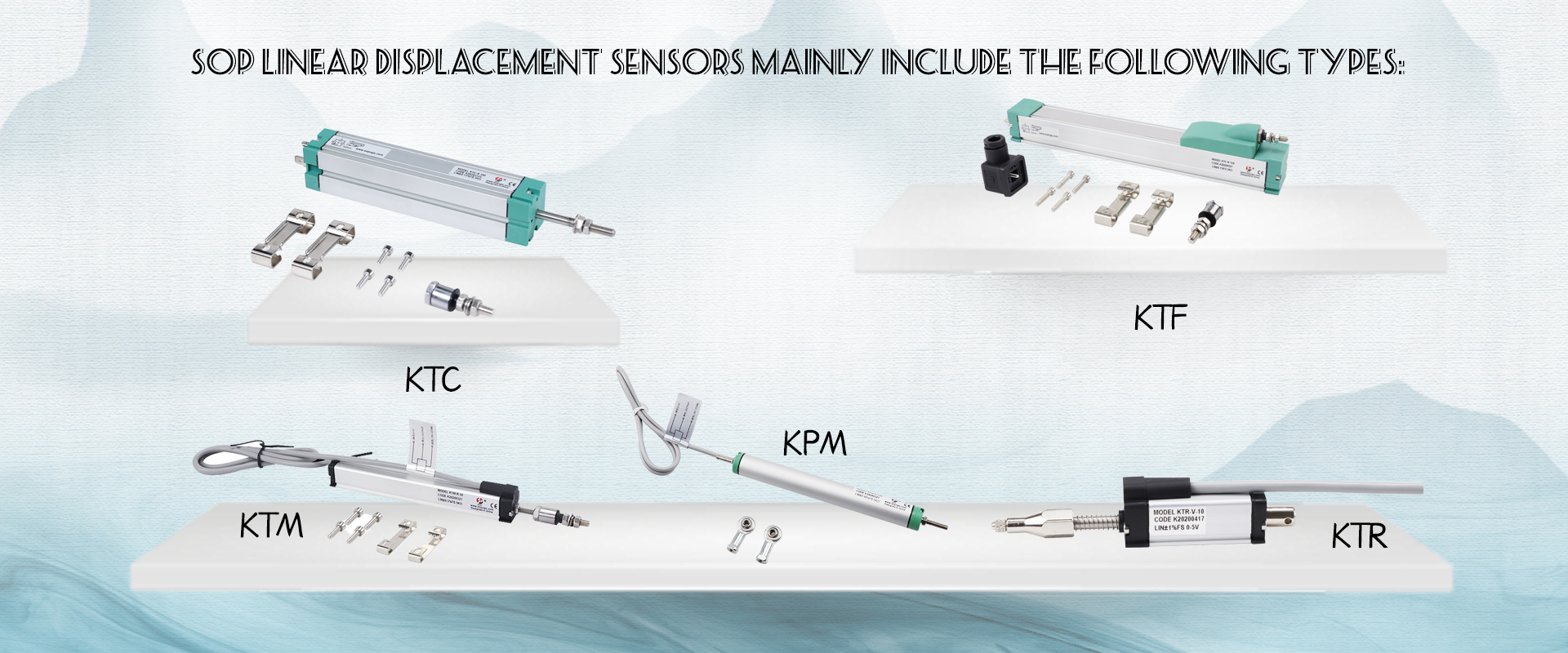

The linear displacement sensor is a potentiometer based resistive displacement sensor, also known as an injection molding machine electronic ruler due to its large application in the field of rubber and plastic machinery. linear displacement sensors are often used as voltage dividers in rubber and plastic machinery, indicating the displacement changes and actual positions of the device driver with relative voltage.

In practical applications, the measuring rod (or slider) of a linear displacement sensor is directly connected to the driver of the mechanical equipment. The driver drives the internal sliding brush of the sensor to undergo displacement changes, and outputs a linearly changing DC voltage signal, which is supplied to the supporting display control instrument or acquisition system for measurement and control. The voltage signal output by the sensor can also be converted into a standard analog signal through a V/I conversion module to meet the needs of long-distance transmission.

Installation and usage precautions:

1. Linear displacement sensors should be avoided from overtravel during use, and a margin should be left in the selection for easy installation and use.

2. The installation of linear displacement sensors adopts a bracket fixed form, and then the follower axis is connected to the measured moving object. When installing a fixed sensor, the remaining dimensions can be evenly distributed at both ends, and the sensor bracket screws can be tightened after the travel adjustment is completed.

3. During the installation and use of sensors (rod series linear displacement sensors and slider series linear displacement sensors), attention should be paid to the installation method and installation neutrality. The installation method can be horizontally or vertically installed. When installing horizontally, it is necessary to ensure that the conductive circuit board is installed downwards to avoid the intrusion of dust, oil, and water on the conductive circuit board, which may cause poor contact or short circuit between the sliding brush of the sensor and the carbon film circuit board.

4. The alignment of the sensor rod or extension rod directly determines the measurement accuracy, detection stability, and service life of the linear displacement sensor. Excessive tilt angles can seriously affect the product performance and service life of the sensor.

5. The wiring issue of linear displacement sensors is also a problem that needs attention. The power and signal wires of the sensor cannot be connected incorrectly. Often, users may cause damage to the sensor due to incorrect wiring.

The use of displacement sensors also requires attention to stable power supply voltage, reliable grounding during installation, and avoiding interference from high-power power sources, RF signal sources, and strong electrical lines to prevent external interference from causing measurement data distortion and affecting measurement control effectiveness. This is not only applicable to linear displacement sensors, but also requires special attention when using other types of displacement sensors.