A New Pressure Transmitter Capable Of Measuring Liquid And Gas: Sop-102

A New Pressure Transmitter Capable Of Measuring Liquid And Gas: SOP-102

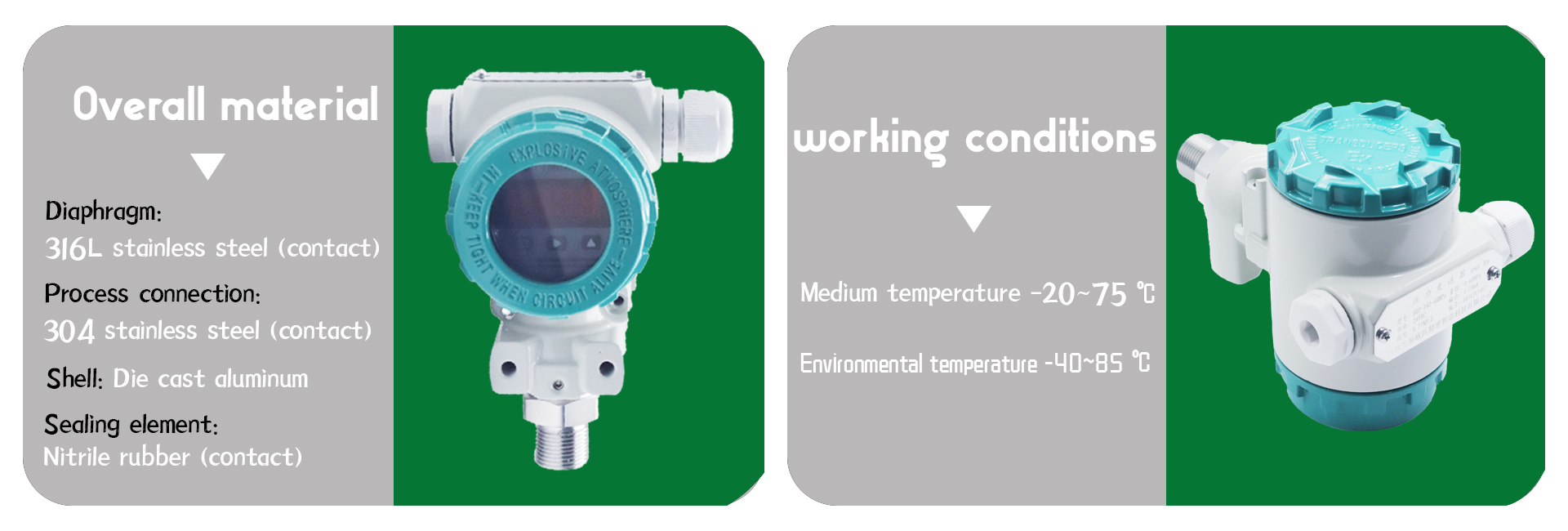

SOP-102 is a new pressure transmitter launched by Jiangxi SOP Precision Intelligent Manufacturing Technology Co., Ltd. This pressure transmitter product uses a high-performance silicon piezoresistive oil filled core, which has been automatically tested by a computer and compensated for zero point and sensitivity temperature over a wide temperature range using laser resistance adjustment technology. The amplification circuit is located inside a stainless steel casing, which converts the sensor signal into a standard voltage, current, or frequency signal, fully leveraging the technical advantages of the sensor and enabling the pressure transmitter to have excellent performance. It has strong anti-interference, overload and impact resistance, low temperature drift, high stability, and high measurement accuracy, making it an ideal pressure measuring instrument in the field of industrial automation.

SOP-102 has the following product features:

1. Adopting advanced membrane isolation technology

2. Integrated chip, wide voltage power supply

3. Compact structure and easy installation

4. Cut off design, strong anti-interference ability, lightning protection

5. Current limiting, voltage limiting, and reverse polarity protection (limited to current output only)

6. High precision, good stability, fast response speed, and impact resistance

7. The measurable medium is liquid or gas (compatible with the contact material). If it is a dry gas specific type, it can only measure dry and non corrosive gases.

Pressure transmitter is a common industrial automation control equipment, which spreads a Wheatstone bridge on a single crystal silicon wafer. The measured medium (gas or liquid) applies pressure to change the resistance value of the bridge wall (piezoresistive effect), generating a differential voltage signal. This signal is amplified by a dedicated amplifier to convert the signal corresponding to the range into a standard analog signal or digital signal. In industrial production, pressure transmitters are widely used in various pressure measurement and control applications, such as chemical, petroleum, natural gas, power, food and other industries. So what should we pay attention to when using a pressure transmitter for the first time?

1. Pre installation inspection: Before installing the pressure transmitter, please check whether the model, specifications, range, accuracy, etc. of the transmitter meet the requirements. At the same time, it is necessary to check whether the appearance of the transmitter is damaged or corroded, and clean the installation position.

2. Installation location selection: The installation location of the pressure transmitter should be as close as possible to the measurement point to ensure stability and reliability. At the same time, the protection level of the transmitter and environmental conditions such as temperature, humidity, corrosiveness, etc. must be considered.

3. Installation method selection: Depending on the actual situation, different installation methods can be chosen, such as flange connection, threaded connection, plug-in connection, etc. Flange connections are suitable for large-diameter pipelines and high-pressure applications, threaded connections are suitable for small-diameter pipelines and low-pressure applications, and plug-in connections are suitable for measuring liquid media.

4. Connection line connection: When connecting the connection line, please follow the transmitter wiring diagram, pay attention to the accuracy and reliability of the wiring, and ensure that the wiring terminals are securely fastened.

5. Zeroing and range adjustment: After installation, zeroing and range adjustment are required. Zero adjustment refers to adjusting the output signal of the transmitter to zero without applying pressure, and range adjustment refers to adjusting the output signal of the transmitter to the desired range.

6. Operation monitoring: After installation, it is necessary to conduct operation monitoring, check whether the transmitter output signal is stable and accurate, and perform necessary calibration and adjustment.

After understanding the basic characteristics and usage precautions of pressure transmitters, let's now learn about their application:

Firstly, pressure transmitters play an important role in the petrochemical industry. In the process of petrochemical production, it is necessary to monitor and control the pressure of various media to ensure the safety and stability of production. The pressure transmitter can convert the pressure signal of the medium into an electrical signal and transmit it to the monitoring system, achieving real-time monitoring and control of the production process. At the same time, pressure transmitters can also be used for pressure monitoring in oil wells, helping to improve the efficiency of oil field extraction.

Secondly, pressure transmitters have a wide range of applications in the food industry. In the process of food processing, it is necessary to monitor and control the pressure of various media to ensure the quality and safety of the product. Pressure transmitters can monitor pressure changes in real-time during food processing, helping manufacturers grasp the real-time situation of the production process and adjust production parameters in a timely manner to ensure product quality and safety.

As an important pressure measurement and conversion device, pressure transmitters have a wide range of applications in the industrial field. It can not only help enterprises achieve automation and intelligence in the production process, improve production efficiency and product quality, but also ensure the safety and stability of the production process. With the continuous development of industry and technological advancement, the application range of pressure transmitters will become increasingly wide, bringing more convenience and opportunities to the development of various industries.