Application and installation requirements of dynamic torque sensors

Application and installation requirements of dynamic torque sensors

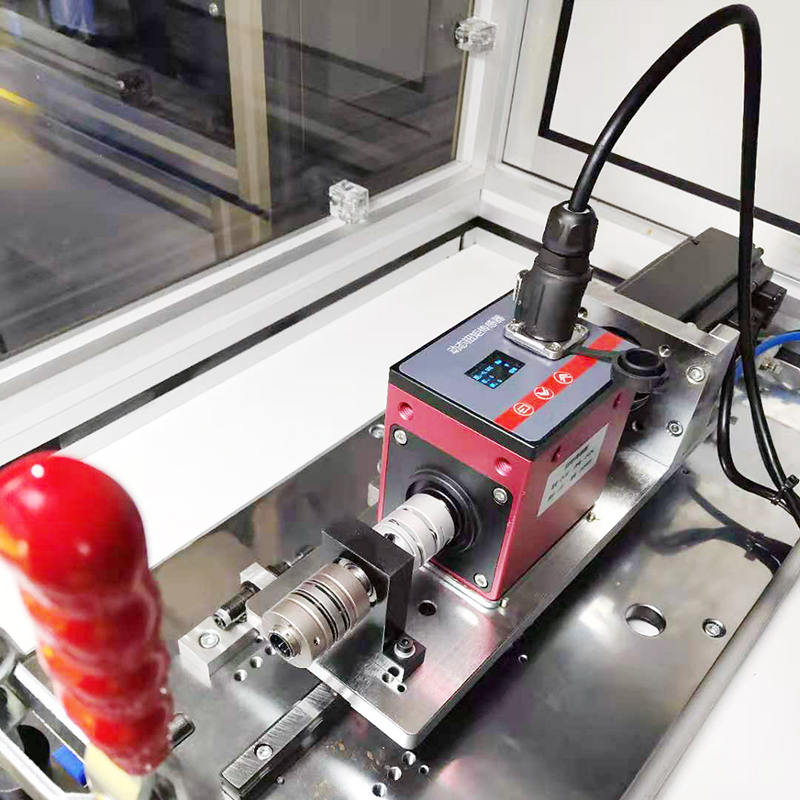

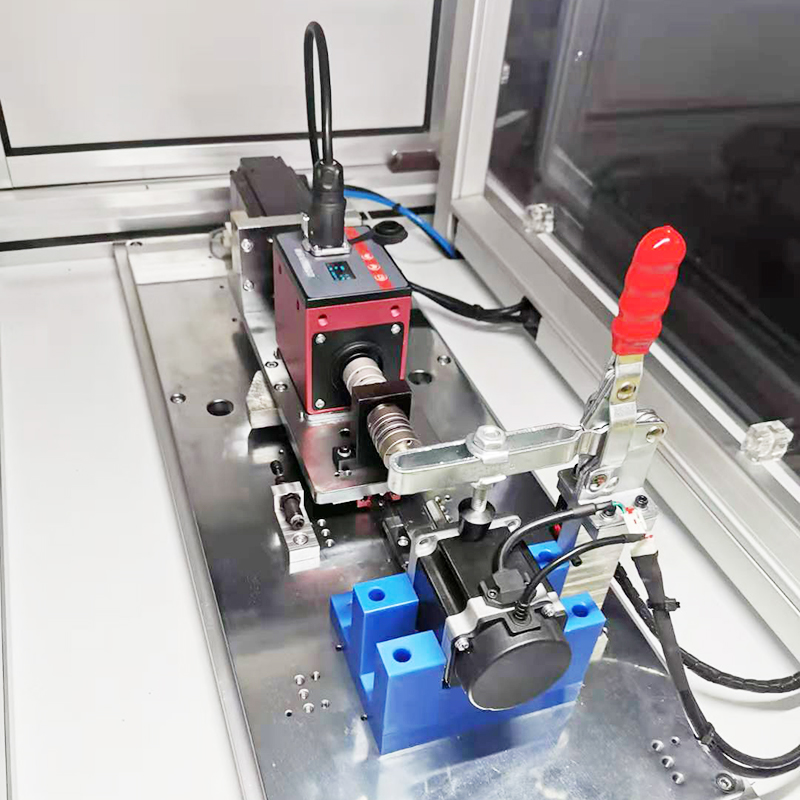

Dynamic torque sensor is a precision measuring instrument that can measure various torques, speeds, and mechanical power. Also known as torque sensor, torque meter,dynamic torque sensor has a wide range of applications. Next, let's learn about the application and installation requirementsof dynamic torque sensors together:

1. Detect the output torque and power of rotating power equipment such as electric motors, engines, and internal combustion engines;

2. Test the torque and power of fans, water pumps, gearboxes, and torque wrenches; Used in laboratories, explosion-proof torque sensor manufacturers, testing departments, as well as production monitoring and quality control;

3. Torque and power testing in railway locomotives, automobiles, tractors, airplanes, ships, and mining machinery.

4. Used for torque and power detection in sewage treatment systems;

5. Can be used to manufacture viscometers;

6. Can be used in process industry and process industry;

Dynamic torque sensors have the advantages of short contact working mode, long contact time, long service life, high reliability, strong anti-interference ability, high accuracy, good stability, and easy installation. It is not easy to wear, has a small delay, and is less affected by axial deflection and axial deflection. It has been widely used in automotive platforms and various industries.

Before using a dynamic torque sensor, it is necessary to install it correctly and reasonably. What are the installation requirements for a dynamic torque sensor? Next, let's learn about the installation requirements for dynamic torque sensors together:

1. Use two sets of couplings to install torque sensors between the power supply and the load

2. Measure the shaft diameter and center height of the dynamic torque sensor

3. The power supply and load equipment of the dynamic torque sensor must be fixed and secured to avoid vibration

4. Securely fix the base of the torque signal sensor onto the base of the equipment to avoid bending moments

5. Sensors can be connected through rigid or elastic couplings. When the vibration is large and the concentricity is less than 0.2mm but greater than 0.05mm, it is recommended to use elastic couplings and motor torque sensors; When the coaxiality is greater than 0.2mm, it is strictly prohibited to use.

6. Regardless of whether the standard sensor is installed horizontally or vertically, it is not allowed for the sensor to withstand excessive axial force and bending moment, otherwise it will affect the use of the sensor and cause damage to the manufacturer of the motor torque sensor.

Before installation, if there is a product manual, please carefully read the product manual that comes with the dynamic torque sensor; If there is no product manual, please contact online customer service in a timely manner if you have any questions. Do not install randomly to avoid damaging the product.