How much do you know about the products of Blower?

How much do you know about the products of Blower?

Jiang Xi SOP Industry Co., Ltd. specializes in producing and selling high-pressure Blower, vacuum pumps, vortex air pumps and other electromechanical products and accessories, and is one of the large-scale manufacturers of high-pressure Blowers in China. So do you all know some basic knowledge about Blowers, including the composition, material and application of Blowers? Next, let's learn more about the Blower!

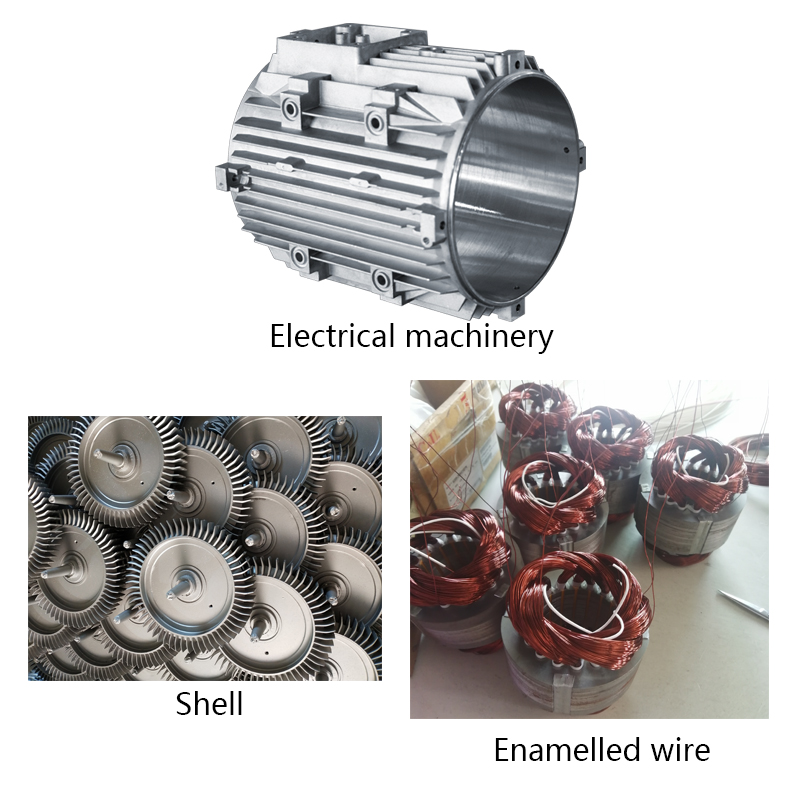

First of all, what are the materials of the Blower? Blower is composed of motor, shell, bearing and impeller, in which motor includes iron core, enameled wire, stator and rotor, impeller, fuselage shell and so on. The enameled wire of motor is divided into pure copper enameled wire and copper-clad aluminum enameled wire. What is the difference between these two enameled wires? In terms of price, pure copper enameled wire is more expensive, while copper-clad aluminum enameled wire is relatively cheaper; In terms of service life, the service life of pure copper enameled wire is long, the high temperature resistance of H-class insulation can reach 180 degrees, and the heat resistance of copper-clad aluminum enameled wire is poor, which is easy to be damaged when heated for a long time, so its service life is not as long as that of pure copper enameled wire; From the use environment, pure copper enameled wire has enough power and power, and there are many applicable environments, while the use environment of copper-clad aluminum enameled wire is limited.

The bearing of the Blower is also an important part of the Blower, so when we make a high-temperature resistant Blower, we need a variety of conditions to achieve it. Pure copper motors, imported bearings, high-temperature oil stains, etc. The bearings with excellent quality are superior in high temperature resistance, wear resistance, corrosion resistance and vibration resistance. With the rapid development of modern economy, Blowers are more and more widely used in all walks of life. Its common application scenarios are: PCB circuit board industry: used to dry the water in the board, and to absorb circuit boards, UV flat-panel printers, cleaning machines, cutting machines, pond culture, inflatable castles and so on.

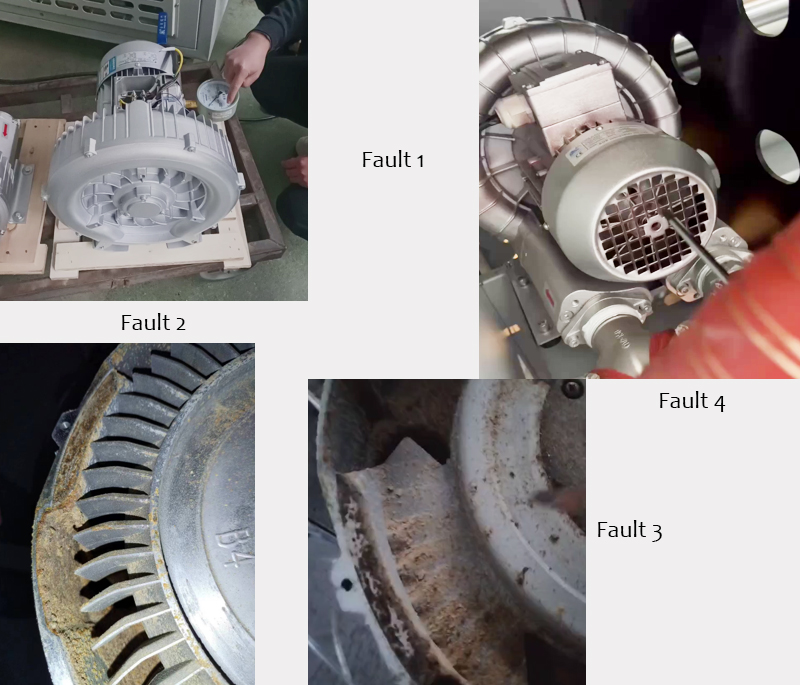

After understanding the material composition and application scene of the Blower, some friends may encounter some problems when using the Blower, such as: the Blower suddenly stops rotating, the noise of the Blower increases, the vibration of the Blower increases, the temperature rises suddenly when the Blower is used, and the pressure/flow of the Blower decreases. If you encounter these problems, don't panic first. It is the key to find out the problem. For example, the Blower suddenly doesn't work: first check whether the power supply is connected, check whether the motor doesn't work, check the motor wiring, and replace the motor if there is any problem with the motor; Check whether the Blower head is damaged, and replace the Blower head if it is damaged; Check whether there is any foreign matter stuck in the Blower. If there is any foreign matter stuck in it, remove it before use. For example, the noise of the Blower suddenly increases. First, check whether the bearing is dry and lubricated. If the bearing is dry, add bearing grease. If the bearing is damaged, it needs to be replaced; Check whether the impeller is worn. If the impeller is worn, it is necessary to replace the impeller or pump head. Loose or falling solid parts will also increase the noise of the Blower, so check whether the firmware is tightened; Check whether there are foreign objects in the Blower, and the noise will increase if there are foreign objects in the Blower, so it is necessary to clean the foreign objects in the Blower in time or replace the pump head.

When using the Blower, you may encounter some other problems, which are not listed here. If you have any questions, please consult online!