How much do you know about dynamic torque sensors?

How much do you know about dynamic torque sensors?

With the development of the economy, the application of dynamic torque sensors in various industries is becoming increasingly widespread, such as:

1. Detection of output torque and power of rotating power equipment such as electric motors, engines, and internal combustion engines;

2. Testing of torque and power of fans, water pumps, gearboxes, and torque wrenches;

3. Testing of torque and power in railway locomotives, automobiles, tractors, airplanes, ships, and mining machinery;

4. Can be used for torque and power detection in sewage treatment systems;

5. Can be used to manufacture viscometers;

6. Can be used in process industry and process industry.

So how much do you know about dynamic torque sensors? Next, let's learn some related knowledge about dynamic torque sensors together.

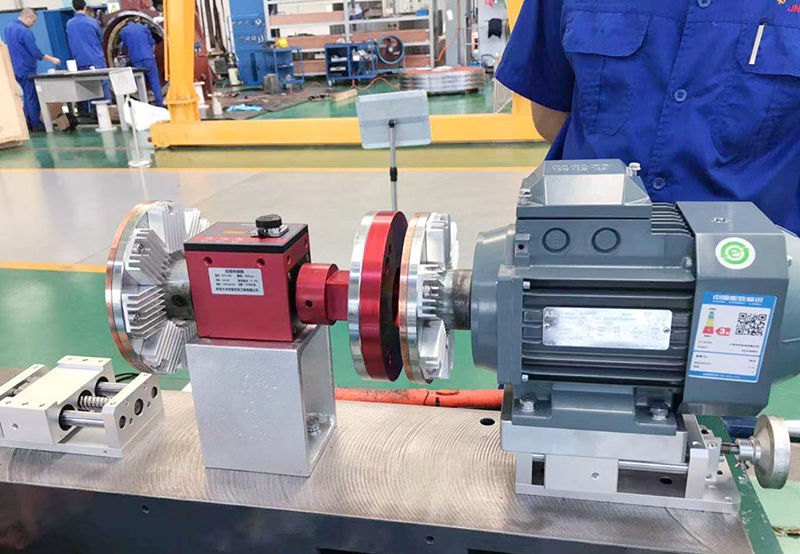

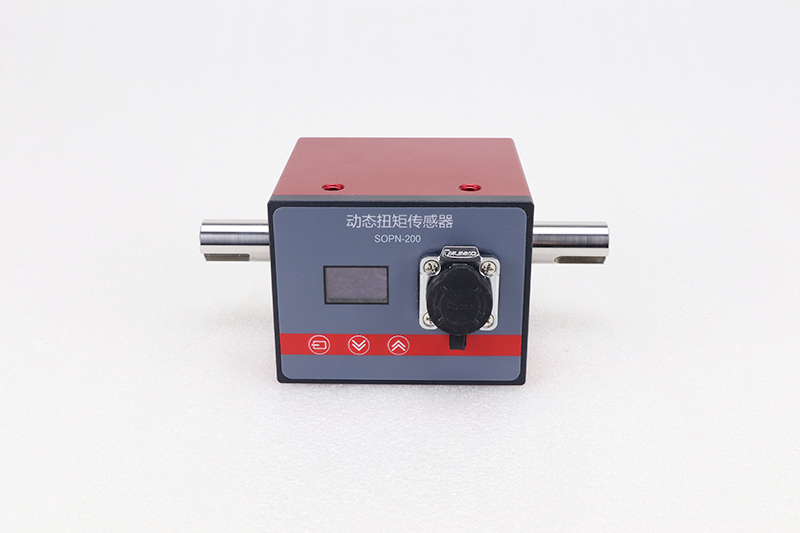

A torque sensor is a precision measuring instrument that measures various torques, speeds, and mechanical power. A dynamic torque sensor, also known as a rotational torque sensor, is a specialized device designed to measure the torque (rotational force) applied to a rotating system (such as a shaft, crank, or axle) in real time. These sensors are crucial for the application of torque dynamic fluctuations and require precise and continuous monitoring to ensure optimal performance and safety. The basic principle of a torque sensor is to use strain gauge electrical measurement technology to form a strain bridge on the elastic shaft, and provide power to the strain bridge to measure the electrical signal of the elastic shaft under torsion. After amplifying the strain signal, it undergoes voltage/frequency conversion and becomes a frequency signal proportional to the torsional strain. After gaining a certain understanding of the basic definition and working principle of torque sensors, what are their characteristics? Next, let's take the dynamic torque sensor SOPN-200 as an example to understand its product features:

1. Real time display of the current measured torque value and speed value

2. It is possible to directly calculate the current power value

3. Supports RS485 communication and active upload protocol

4. Communication speed can reach 500 or 1000 times per second

5. This sensor supports simultaneous output of transmitting current and voltage

6. The sensor comes with an OLED display, with a resolution of 128 * 64

7. Simple calibration, zeroing, filtering, and other operations can be performed

8. Allow sensor overload of 200%

9. Achieved accuracy of over 1/1000 and excellent zero point stability

10. High detection accuracy, good stability, and strong anti-interference ability

When you have understood some basic definitions, working principles, and product features of dynamic torque sensors, and I believe that everyone will be more satisfied when choosing dynamic torque sensors. When you use a new dynamic torque sensor, some friends may feel a headache because they don't know how to install it for the first time? So now let's take a look at how it is installed and used:

1. Based on the connection form of the shaft and the length of the torque sensor, determine the distance between the prime mover and the load, adjust the distance between the axis of the prime mover and the load relative to the reference plane, so that their coaxiality is less than ± 0.03mm, and fix the prime mover and the load on the reference plane.

2. Install the couplings onto their respective shafts.

3. Adjust the distance between the torque sensor and the reference plane to ensure that the coaxiality between its axis and the axis of the prime mover and load is less than ± 0.03mm. Fix the torque sensor on the reference plane.

4. Tighten the coupling and complete the installation.

Special attention should be paid to the installation and use of torque sensors:

1. During installation, do not operate with electricity and do not directly hit or collide with the sensor.

2. The fastening bolts of the coupling should be tightened, and a protective cover should be added on the outside of the coupling to avoid personal injury.

3. The signal line output must not be grounded, short circuited to the power supply, and the output current should not exceed 10mA. The shielding layer of the shielded cable must be connected to the common terminal (power ground) of the+15V power supply.

4. The torque sensor should be installed in an environment with an ambient temperature of 0℃to 60 ℃, a relative humidity of less than 90%, and no flammable or explosive materials. Not suitable for installation in environments with strong electromagnetic interference.

Generally speaking, the service life of torque sensors is relatively long, so paying more attention to their maintenance and upkeep can extend their service life. So, what do we need to do for the maintenance and upkeep of torque sensors?

1. Lubricating grease should be added to the bearings at both ends of the torque sensor every year. When adding grease, only open the bearing covers at both ends, add grease to the bearings, and then install the two end covers.

2. It should be stored in a dry, non corrosive environment with a room temperature of -20 ℃ to 70 ℃.

By achieving these two points, the service life of the torque sensor will not be short. At this point, everyone has gained a certain understanding of dynamic torque sensors. If you want to learn more about torque sensors, other sensors, or purchasing issues, you can consult online or send an email. Thank you!