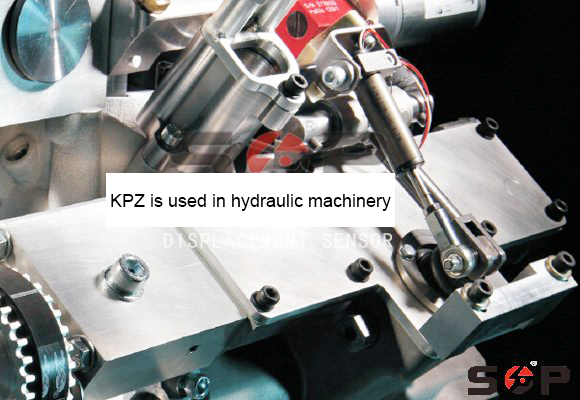

The application of KPZ linear displacement sensor in hydraulic machinery

The application of KPZ linear displacement sensor in hydraulic machinery

KPZ is a miniature rod type linear displacement sensor that can be used in various hydraulic and mechanical applications due to its inherent product characteristics. Before understanding its application, it is necessary to have a basic understanding of its product features. So, what are the product features of KPZ? Here are some of its basic product features:

1. Excellent linearity

2. Resolution higher than 0.01mm

3. High operating speed

4. Suitable for displacement detection inside equipment and chambers

5. Protection level IP65

6. configurable voltage and current (2-wire, 3-wire) module

The precision and durability of KPZ linear displacement sensor make it an ideal choice for the industry and use cases. Here are some of its main applications:

1. Construction equipment

KPZ sensors are widely used in construction machinery to ensure accurate measurement and control. Applications include:

Excavator: Ensure accurate positioning of excavator arms for precise excavation and material handling.

Crane: monitors the extension and retraction of the boom to improve the safety and efficiency of lifting operations.

Bulldozer: Control the height and angle of the blade to maintain accurate flatness and slope.

2. Industrial machinery

In industrial environments, KPZ sensors are crucial for monitoring and controlling various types of equipment, such as:

Hydraulic press: provides precise feedback on the position of the piston in the press, ensuring consistent production quality at all times.

Injection molding machine: monitors the movement of mold components to maintain high precision during the manufacturing process.

Material handling system: Ensure accurate positioning of conveyors, elevators, and other material handling equipment.

3. Agricultural machinery

For agricultural applications, KPZ sensors can improve the performance and efficiency of equipment hydraulic systems, such as:

Tractor: controls the position of hydraulic tools such as plows and rakes to accurately prepare soil and sow seeds.

Harvester: Monitor the position of cutting blades and conveying systems to ensure efficient and accurate harvesting.

Spray: ensure the correct positioning of the spray bar for the uniform application of fertilizers and pesticides.

4. Automobiles and Aerospace

In the automotive and aerospace industries, KPZ sensors are used for precise measurement and control of hydraulic systems, including:

Testing and measurement: Provide accurate displacement data on the hydraulic test bench of vehicle components.

Flight simulator: Ensure precise movement of hydraulic actuators in the flight simulator to obtain a realistic training experience.

Automotive suspension system: monitors the position of the hydraulic suspension to enhance vehicle stability and comfort.

5. Renewable energy systems

KPZ sensors are also used in renewable energy applications, where precise control of hydraulic systems is crucial, such as:

Wind turbine: Monitor the position of the hydraulic pitch control system to optimize the angle of wind turbine blades and achieve maximum efficiency.

Hydroelectric dam: Control the position of hydraulic gates and valves to regulate water flow and energy production.

6. Robots and Automation

In the field of robotics and automation, KPZ sensors provide precise position feedback for hydraulic actuators, thereby achieving:

Mechanical arm: Ensure accurate movement and positioning of hydraulic mechanical arms in manufacturing and assembly lines.

Automatic Guided Vehicle (AGV): monitors the position of the hydraulic lifting mechanism in the AGV for precise handling and transportation of materials.

The versatility and accuracy of KPZ linear displacement sensors make them an indispensable component in many hydraulic mechanical applications. Whether in the fields of construction, industrial machinery, agriculture, automotive, aerospace, renewable energy, or robotics, KPZ sensors can improve performance, accuracy, and reliability, making them a key tool for optimizing hydraulic systems in various industries.