How to reduce damage to displacement sensors?

How to reduce damage to displacement sensors?

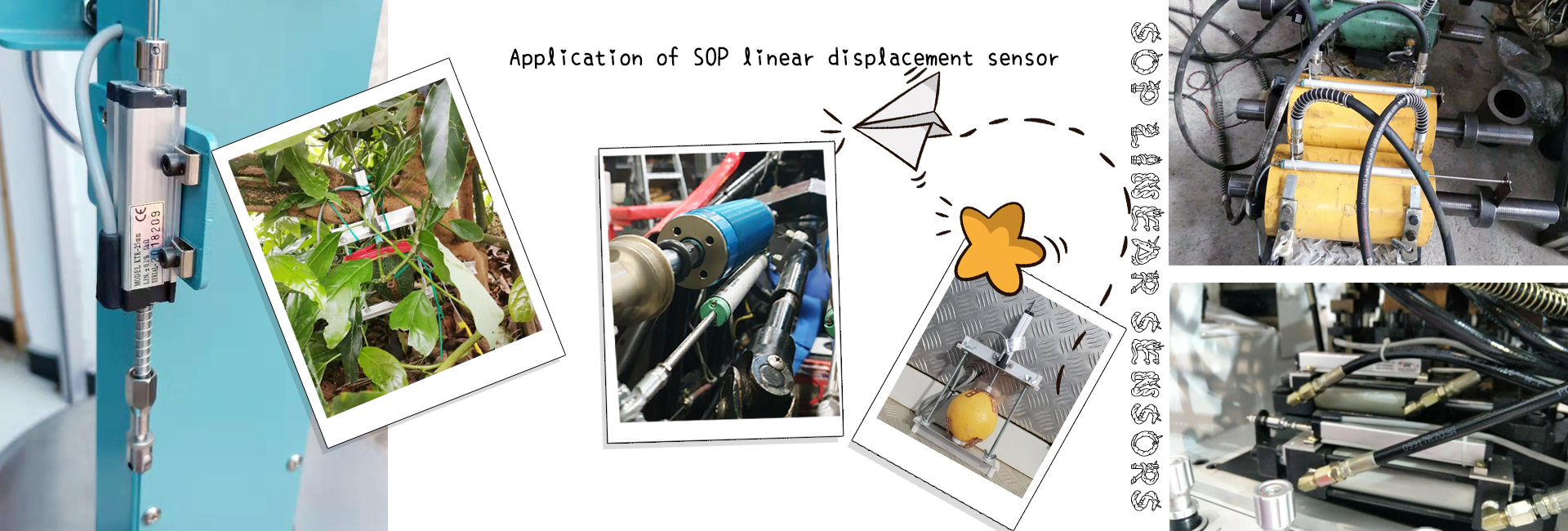

A displacement sensor is a linear device with metal inductive properties that converts various measured physical quantities into electrical quantities when in operation. There are several aspects that are very important when using a linear displacement sensor, otherwise it can easily lead to damage.

Firstly, displacement sensors can easily cause circuit aging and wear due to mechanical motion during use. At the same time, during use, a lot of impurities such as water mixtures and oil can easily enter, which can have a very serious impact on the contact resistance of the electric brush. The common situation is that the data output by the sensor is not very chaotic, and the digital display will frequently bounce. Therefore, the selection of displacement sensors should be based on the reasonable use of the displacement sensor on site.

Secondly, regarding the issue of power supply, we need to exclude displacement sensors that do not require autonomous power supply. Ordinary displacement sensors are powered by 24 volts. If the power supply capacity decreases, the movement of the sol will cause changes or fluctuations in the display of the mold closing electronic ruler, and there may also be mold closing movements that cause fluctuations in the displacement sensor of the glue injection, resulting in significant measurement errors. If the driving power supply of the solenoid valve and the driving power supply of the linear displacement sensor are both together, these situations can easily occur. If the situation is very severe, a multimeter can be used to test voltage fluctuations.

Finally, FM interference and electrostatic interference. To distinguish the signal line of the displacement sensor from the strong wire of the equipment, a grounding bracket should be used for the displacement sensor, and its housing should be in contact with the ground. To check if there is static interference in the displacement sensor, you can use a power cord to connect the cover screw on the displacement sensor to some metal segments on the equipment. Once connected, the static interference will disappear.