-

04-15 2025

Points to note when using a linear displacement sensor

There are many points to pay attention to when using a linear displacement sensor, and now we will elaborate on the following important points:

-

04-08 2025

Advantages and common faults of linear displacement sensors

Linear displacement sensor is a type of sensor used to measure surface deformation or rotational displacement of objects. This type of sensor is widely used, such as in automobiles, machinery, ships, etc., and has many advantages. Below, we will introduce the advantages and common troubleshooting methods of linear displacement sensors for your reference.

-

03-31 2025

Application of LVDT displacement sensor in aerospace field

LVDT (Linear Variable Differential Transformer) is a commonly used displacement sensor with high accuracy, stability, and reliability, making it widely used in the aerospace industry.

-

03-27 2025

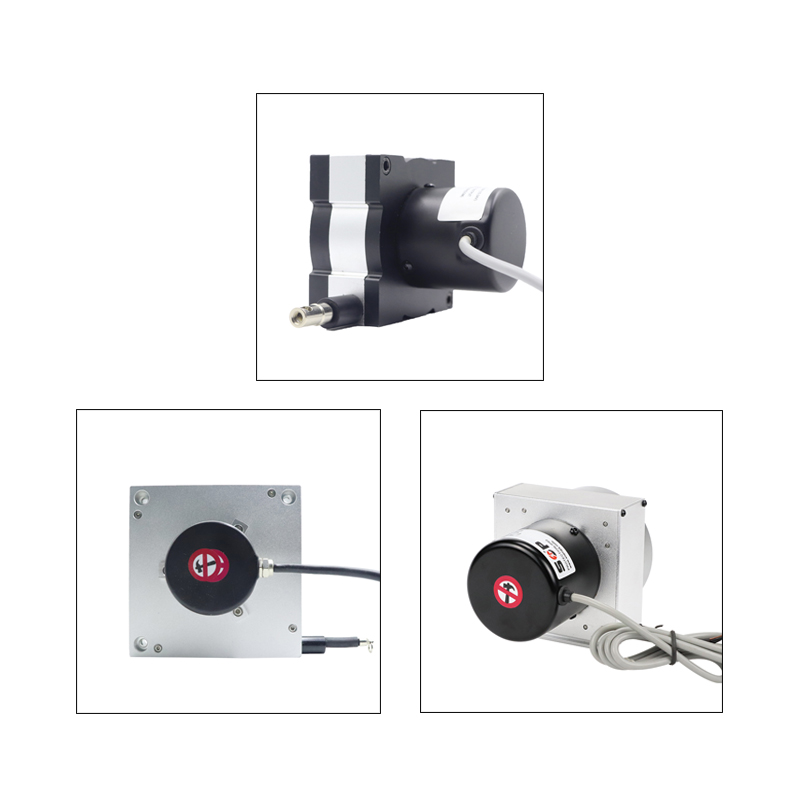

The Application of Draw Wire Sensor in Water Conservancy Gate

Rope displacement sensor, also known as rope sensor, rope electronic ruler and rope encoder, is a kind of sensor used to measure linear position. It combines the advantages of angle sensor and linear displacement sensor, and has the characteristics of small installation size, compact structure, large measuring stroke and high precision, ranging from hundreds of millimeters to tens of meters. Measuring the opening of the gate: the pull-rope/linear displacement sensor can directly measure the displacement of the gate leaf or arm, thus indirectly reflecting the opening of the gate.

-

03-21 2025

Function of Displacement Sensor in Internet

With the development of economy, the application scope of linear displacement sensor is becoming wider and wider. Today, we will learn about the application of linear displacement sensor in the Internet, which is mainly reflected in the following aspects:

-

02-17 2025

Selection of rope displacement sensors

A little carelessness in product selection will lead to poor measurement accuracy or unavailability. Therefore, it is necessary to understand the meaning of the rope displacement sensor when selecting the model, and then purchase it, so as not to cause unnecessary trouble. Here, we will summarize the matters needing attention in the product selection process of the cable displacement sensor:

-

02-10 2025

Application of Linear Displacement Sensor in Plant Growth Monitoring

Plant growth detection is an important task in fields such as ecology, forestry, and agricultural technology. In order to accurately grasp the growth laws of plants, understand their growth mechanisms, and provide scientific basis for plant cultivation and agricultural management, the application of modern technological means such as linear displacement sensors is particularly important. The application case of linear displacement sensor in plant growth detection demonstrates its advantages of high precision, reliability, and automated measurement.

-

02-07 2025

Reasons and solutions for overload fault of High pressure blower motor

What should we do if there is a motor overload fault when we use a high-pressure blower? Firstly, we need to identify the cause of the malfunction and then come up with a solution. Now, let's take a look at the reasons for the overload fault of the high-voltage blower motor? And how to deal with these faults?

-

01-21 2025

How to correctly install a high-pressure ring blower to improve its working efficiency?

The incorrect installation method of a high-pressure ring blower can affect its working efficiency. So, how can we install a high-pressure ring blower to improve its working efficiency?

-

01-14 2025

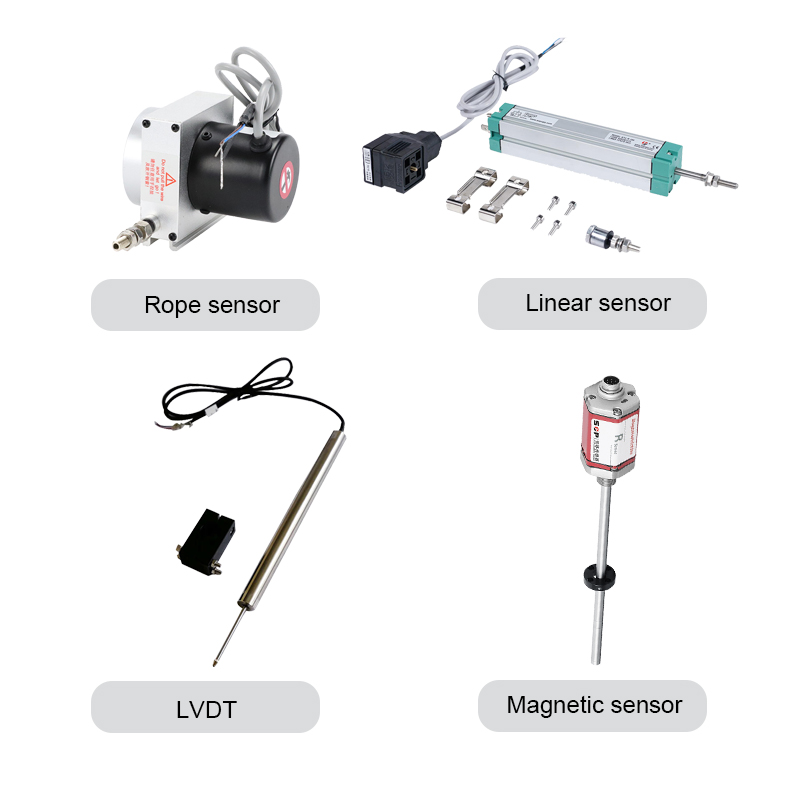

Application of Linear Displacement Sensor in Bridge Inspection

Jiangxi SOP Precision Intelligent Manufacturing Technology Co., Ltd. is a high-tech enterprise specializing in sensor technology research and development, design, manufacturing and sales. The company has experts engaged in sensor technology for nearly 20 years, gathered many experienced engineers and technicians, has strong technical strength of independent research and development of high-tech products, and has fully functional high-precision production testing equipment. Provide displacement sensor products and solutions. Our company's main products are linear displacement sensor, cable displacement sensor, LVDT displacement sensor, magnetostrictive displacement sensor, weighing sensor, pressure sensor, torque sensor, ultrasonic flowmeter and so on. Products are widely used in machinery manufacturing, automobile, metallurgy, petroleum, chemical industry, scientific research institutes, aerospace and other fields.